BACK TO PREVIOUS HOMESTEAD PAGES

November Homestead

*********New

Pics of Bob's World 11-11-04*********

Link: Erwin

Invitational Air Pistol Shoot

Welcome Friends.

I'd like you to know that the Homestead

Concept is working very well. I'm enjoying your conversation and

comments. Sincerely. It's a welcome place to visit. Thanks for

participating.

11-30-04

Well, we've had a busy November. Hope

you have enjoyed these pages.

New URL for December

is now in effect.

One quick subject I hope you will help

me with just now. Since you are all regular readers, you will

have followed along with many things (for better or worse) that

I've attended to over the past months. There's never enough of

me to go around.

As you've enjoyed the Homestead side,

I do too. One little point of stress though I've created for myself.

Obviously, individual project progress is key in everyone's curiosity.

You may follow that I wish I could report great leaping strides

on everyone's individual project each time we speak. I can't.

Great strides on some - less on others.

Things come up like I must face this

morning. There's a truck bearing down on my shop from Atlanta,

Ga. It carries a 900 pound band saw that I've needed for the past

30 years while I've used my little altered one. That shop's door

is blocked with equipment and there's no room for it. I have to

make a hole. So, that's gonna cut into somebody's project today.

I apologize.

I've been dancing as fast as I can.

Dragging along as much with me as possible. I tell you what's

been going on and I hope you enjoy seeing what I have gotten complete.

I promise that yours is in the works. I don't play golf. ;?)

Thanks sincerely,

Gary

11-29-04

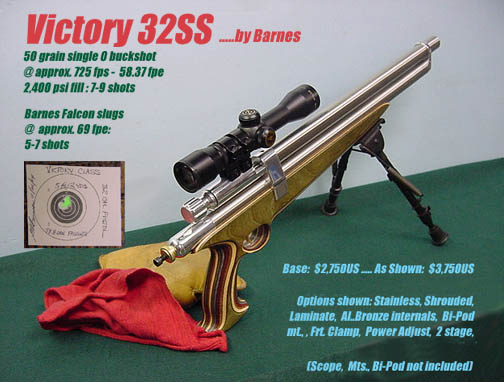

Victory

32 SS Movie

11-29-04

Had the Yukon 58 GS out to the farm

this windy afternoon. I've had an excellent Thanksgiving break.

wonderful to have gotten in some shooting. Much needed ... I'd

almost forgotten how. ;?)

Take a look at the movie I made from

the footage I shot today at the range.

Yukon 58

GS Movie

11-27-04

Please take another

look at the "Base

Model Barnes"

page if you'd like a description of where my work starts.

Welcome Friends.

I'd like you to know that the Homestead

Concept is working very well. I'm enjoying your conversation and

comments. Sincerely. It's a welcome place to visit. Thanks for

participating.

11-30-04

Well, we've had a busy November. Hope

you have enjoyed these pages.

New URL for December

is now in effect.

One quick subject I hope you will help

me with just now. Since you are all regular readers, you will

have followed along with many things (for better or worse) that

I've attended to over the past months. There's never enough of

me to go around.

As you've enjoyed the Homestead side,

I do too. One little point of stress though I've created for myself.

Obviously, individual project progress is key in everyone's curiosity.

You may follow that I wish I could report great leaping strides

on everyone's individual project each time we speak. I can't.

Great strides on some - less on others.

Things come up like I must face this

morning. There's a truck bearing down on my shop from Atlanta,

Ga. It carries a 900 pound band saw that I've needed for the past

30 years while I've used my little altered one. That shop's door

is blocked with equipment and there's no room for it. I have to

make a hole. So, that's gonna cut into somebody's project today.

I apologize.

I've been dancing as fast as I can.

Dragging along as much with me as possible. I tell you what's

been going on and I hope you enjoy seeing what I have gotten complete.

I promise that yours is in the works. I don't play golf. ;?)

Thanks sincerely,

Gary

11-29-04

Victory

32 SS Movie

11-29-04

Had the Yukon 58 GS out to the farm

this windy afternoon. I've had an excellent Thanksgiving break.

wonderful to have gotten in some shooting. Much needed ... I'd

almost forgotten how. ;?)

Take a look at the movie I made from

the footage I shot today at the range.

Yukon 58

GS Movie

11-27-04

Please take another

look at the "Base

Model Barnes"

page if you'd like a description of where my work starts.

_

_ Was shooting the Barnes

83 grain Shrike slug today some. 71 fpe. This is why some may

not have considered pistols before. However; most will agree this

is a different world from what you've experienced before.

Really coveres the

storage, handling, transportation, and weight issues.

Just filling you in.

Not trying to change the world. Just showing you another page

or two of what's possible here in the shop.

We'll talk more ...

11-27-04

Was shooting the Barnes

83 grain Shrike slug today some. 71 fpe. This is why some may

not have considered pistols before. However; most will agree this

is a different world from what you've experienced before.

Really coveres the

storage, handling, transportation, and weight issues.

Just filling you in.

Not trying to change the world. Just showing you another page

or two of what's possible here in the shop.

We'll talk more ...

11-27-04

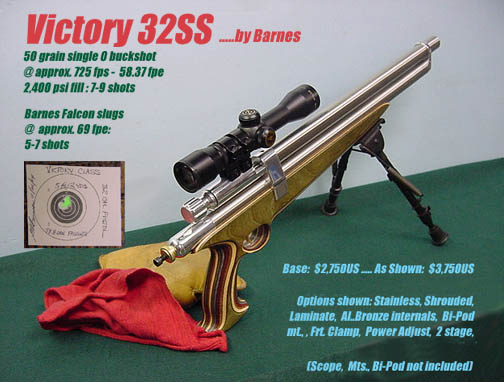

A number of you have been talking to

me throughout the past year. Some of you joined the ledger without

choosing a specific model. We've discussed the development program

which has been on-going for the last 18 months or so. I've mentioned

the "Victory Class" to some of you. This is a pistol

version that has been in testing. A Pistol Carbine version is

available (out-rigger rear shoulder stock). This action could

also be mounted in a carbine rifle stock format.

As was discussed in the long post (11-15-04),

I often do not build the base model first. The "Base"

model is just as custom as any other pc. I'd build. Therefore;

the one I've assembled and have been testing has a number of features

many ask about.

We've enjoyed a wonderful Thanksgiving

break - yes. Thanks for your notes.

In the shop, I've finally decided to

give one of my old bandsaws the retirement I'll never have. ;?)

A simple wood cutting bandsaw I converted to cut metal 30 years

ago. I've nursed it along. Today I told them to send me one like

the big boys use - blade welder and all. I feel like a kid at

Christmas. Now, I just have to get the elves to move everything

so it can come into the shop. ;?)

The turkey sandwiches are going down

very well - yes ... washed by a cup of coffee. The Bison are wandering

around in the shop. It's been cold and windy outside - Oh ...

some of you tell me very kind things from time to time. I appreciate

it very much. Maybe some of you will appreciate something that

I appreciate. Try the CD's of Allison Krauss. Her voice is one

of God's gifts to all our ears. From a background of Bluegrass,

her songs cover a wide range of styles. You'll find several that

will make you simply stop and marvel.

Well, it's almost 2am. I see the Tryptophan

hasn't really burnt thru the caffeine yet. Hummm ... better get

upstairs anyway.

;?)

Gary

11-25-04

A number of you have been talking to

me throughout the past year. Some of you joined the ledger without

choosing a specific model. We've discussed the development program

which has been on-going for the last 18 months or so. I've mentioned

the "Victory Class" to some of you. This is a pistol

version that has been in testing. A Pistol Carbine version is

available (out-rigger rear shoulder stock). This action could

also be mounted in a carbine rifle stock format.

As was discussed in the long post (11-15-04),

I often do not build the base model first. The "Base"

model is just as custom as any other pc. I'd build. Therefore;

the one I've assembled and have been testing has a number of features

many ask about.

We've enjoyed a wonderful Thanksgiving

break - yes. Thanks for your notes.

In the shop, I've finally decided to

give one of my old bandsaws the retirement I'll never have. ;?)

A simple wood cutting bandsaw I converted to cut metal 30 years

ago. I've nursed it along. Today I told them to send me one like

the big boys use - blade welder and all. I feel like a kid at

Christmas. Now, I just have to get the elves to move everything

so it can come into the shop. ;?)

The turkey sandwiches are going down

very well - yes ... washed by a cup of coffee. The Bison are wandering

around in the shop. It's been cold and windy outside - Oh ...

some of you tell me very kind things from time to time. I appreciate

it very much. Maybe some of you will appreciate something that

I appreciate. Try the CD's of Allison Krauss. Her voice is one

of God's gifts to all our ears. From a background of Bluegrass,

her songs cover a wide range of styles. You'll find several that

will make you simply stop and marvel.

Well, it's almost 2am. I see the Tryptophan

hasn't really burnt thru the caffeine yet. Hummm ... better get

upstairs anyway.

;?)

Gary

11-25-04

Happy Thanksgiving

I hope you all enjoy

a time of relaxation and find that you are blessed.

I plan to actually

do alittle shooting this morning. It's been way too long since

I shot for fun. I hardly even got to shoot at SS4 again.

We'll go to our Son's

home for a great meal later today. Yummmmm.

Been alot of mail correspondence

lately. I appreciate your notes. I'm moving projects along. Turning

the shop into a Bison workshop now. I'm into four of them good

folks are waiting for.

No ... nobody ever

took the free firewood. One of our Homestead friends said he'd

like to have it but I'd have to drive it to Alaska for him ...

;?) Hummmm ..... I had to haul it away.

It's been real good

to be in the shop working. I have the warm fuzzies with the thought

of the winter workshop and completing things.

We have a small group

committed to the Erwin Cup Pistol shoot - Jan. 15,16, '05 in Corbin,

Kentucky. That will be a fun time. Bob is fluffing up all the

targets for us.

Sorry I'm behind where

I'd like to be but I'm gaining some ground. I know I haven't posted

as much - been trying for alittle more shop time.

Some of you have picked

up on the "pistol" threads and asked about them. I'm

fascinated that there's so much that can be done with them that

answers what many people try to meet with their rifles. I agree

that the very low power short barrel variety of pistol are somewhat

limited. Those are great for indoor target and back yard enjoyment.

The "Pistols" I'm making are in a bit of a different

category. They're all "Pistol-Mags".

Mine are units that

could be at home in a small carbine stock. I started out making

things like this and got away from it as more and more folks were

intrigued by the big - long reaching rifles. Now I'm very much

enjoying both. My pistols are an interesting compromise. A third

to a half the weight of the rifles. About a quarter or a third

the length of a rifle. Yet my pistols are deadly accurate and

generate the power of most of the commercial PCP rifles of the

same caliber. Easy to store - easy to carry around. With power

adjust, easy to turn down for an indoor range if you wish. A neat

alternative.

Think I'll go shoot

a few rounds before Turkey! ;?)

Best of all to you

... Gary

11-19-04

Yes, I'm here. Thanks

for asking.

Working on parts. Working

on some crates for shipping. Worked on some more clean-up around

here. It's not the sort of thing you just give a kid a few bucks

to do. Not anymore anyway. Nothing's simple. I bought the place

in 1980. Young and stupid, I planted shade trees and yew shrubs

and ornamental trees and juniper bushes and juniper ground cover,

and azalea, and bamboo, etc., etc. Now, 25 years later, I'm ready

to lay waste to the whole darned forest. I must have been out

of my mind!

Thanks ... don't tell

me I was the last person on earth to find out that bamboo is aggressive.

Heard it all. Everybody else learned that in pre-school. Grew

up with a full knowledge of oriental horticulture. Well, I went

before they had pre-school ... so I missed all that. But I can

tell you things you don't even WANT to know about it now ... ha

ha ;?)

Story for you. I had

a bunch of construction materials stored - in waiting for a tool

shed addition to the shop. You know - the hundred hand tools,

the mower, snowblower, weed whackers, leaf blower, pressure washer,

chipper, mulcher, etc., etc.

So, the materials were

waiting there - in the way. And, one of these stupid ornamental

trees I'd planted - a flowering crab apple - was in the way -

they're ALL in the way. So, don't tell anyone ... I cut the thing

down. Then, the pile of tree brush and wood was in the way....

;?(

So, here and there,

I've moved the materials, cut the tree, moved the debris ... maybe

six months ago I framed the addition and roofed it ... later I

did alittle more. At this time, it has some cribbing up for walls

with some cedar shingle on the back - the weather side is just

a ladder work of cribbing the shingles go on. Whenever ... I have

no time to fiddle with it now.

So, many of these materials

that I'd accumulated were just never used. In the way. Some second

hand and ... waiting for years ... they were just not fresh enough

now. So, today, I cut up a bunch of 6 by 6 posts that were real

nice about 20+ years ago. Still solid ... but not what you invest

time into building with now. I'd acquired a bunch of packs of

1 by 3 lathing. I mean a dozen bundles of it or so ... but - weather,

cooking under tarps, bugs, etc. ... not fresh now. Cut it up.

Had some big limb stock - cut that up. Laid it all neatly in the

back of the truck. Cut into 3-4' lengths. Full load - tires showing

the weight and the truck down from the weight.

Around here, I've set

things out with FREE signs on them now and then, Usually gone

in half an hour. I decided someone could use all this clean firewood.

Put a sign out referring them around back to the truck - free

firewood.

All day, trucks drove

by in the alley - stopped - then drove on. So, good news ... the

economy is booming. Nobody needs a truckload of free firewood.

Maybe if it was seasoned split white oak and I'd deliver it and

stack it for them, someone would take it. Man, 25 years ago I'd

have thought it was Christmas if someone had given me this stuff.

Things have changed.

Still needing some

confirmation from a few for our Erwin Pistol Shoot. If you'd like

to spend the weekend with some folks enjoying Barnes Pistols,

let us know. You'll regret it for the rest of your lif.... well

... maybe not ... but we'd enjoy your company. It's intended to

be a small group and we have a few. But, for now, we have room

for a few more.

11-15-04 (amended

11-16-04)

If there's been a defining

discussion here on the website, I think this one - poised to snap

off of my fingers onto the keyboard may be it. You'll need a cup

of coffee or tea - and a few cookies. ;?)

Read it when you have

time to enjoy it. It's just a bunch of thoughts that came together

at this point.

How do I do this? I

mean ... really. Not how does the reservoir screw onto the valve

body, I mean .... HOW do I manufacture the products you see on

these pages. Some of you will find this fascinating ... some of

you will find it frustrating. Maybe this should be over on the

Homestead side, because it requires a simple faith in the fact

that I'm not "spinning" anything here. This is THE inside

information that goes to the core of Barnes Pneumatic. Ready?

OK, I've taught myself

to think in and to build "concepts". Concepts - not

artifacts. The one key invention which allowed the entire industrial

revolution was ..... "the interchangeable part". It

allowed unskilled labor to produce quality goods. Let me beat

that to death. That means that you can get a parts list for a

1963 Ford Falcon, and you can order up any of those parts, and

they will fit onto your 1963 Falcon. Big deal. So what?

Do you know what it

took to do that? Tens of millions of dollars for a start. A key

team of engineers design the concept. They are the ones who need

to know how the thing works. Not just that part # 465-KNY may

eventually be an exhaust valve for a six cylinder internal combustion

engine, rather ... they need to be able to DESIGN an internal

combustion engine and know what that exhaust valve needs to do.

What steel does it need to be made from? What shape does it need

to be. What diameter? What degree of bevel? What seat material

will it mate with? How will it be effected by heat? What spring

pre-load will snap it shut ... for the next twenty years and one

hundred million cycles?

Oh, eventually, you

can look that stuff up in mechanical engineering texts. Maybe.

Maybe if there is a text on the subject. Maybe if it's not a new

concept. Maybe if you can FIND the material you need and relate

it to the application you require. Then, maybe you can find some

of the information.

As the original engineer

however, you need to have an "instinct" for the original

concept. You need to be able to visualize your part in motion

... within the working swarm of all the other dependent parts

of the project. And then, you fabricate that prototype exhaust

valve - the one you saw in your mind. And, when it's complete,

you document the steps you took to make it. The casting and/or

machining. The lathe work. The heat treating. The dimensions.

The allowable tolerances.

For production, with

hundreds of thousands of dollars in equipment and labor, you set

up an entire system whereby workers (who know surprisingly little

about the given object), can run machinery which produces those

exhaust valves by the crate full. At that point, with sufficient

quality control and ongoing maintenance of equipment, you can

take any of those exhaust valves out of any crate and install

them into the engine of your 63 Falcon six cylinder.

Now, all you need is

to do the exact same thing for each of the other 20,000 parts

in the car.

We take all of this

for granted. It's the way industry has worked for the last 150

years. The interchangeable part, made by the thousand, was the

key. It requires factories - shifts of workers - vast tooling

maintenance - and incredible amounts of capital investment.

Fast forward. Do I

do that? No. Can I do that? No ... not just like that. Look into

the crystal ball again .... what did man do for the next generation

of the "interchangeable part"? Labor became organized

and expensive to maintain at about the same time as the electronics

revolution. Manufactured brains ... PC's ... came into being.

You didn't have to find a natural engineer who could visualize

the unknown. You just programed the PC's brain the do a repetitive

series of operations ... exactly the same for time without end.

And, to accompany the brain, you needed the most incredible computer

operated machine equipment ....CNC. You didn't specifically have

to make crates and crates of the same part (though you could).

In reality, you had your magic replicator which stored the method

of making your parts on demand. Your millions of dollars now transferred

from your labor force into your hardware investment. You began

to exist just to service the hardware. Keep it running. Keep the

brain cool and dust free. Make the payments on the equipment.

Fly in the specialized technicians to calibrate the things when

they go weird on you. Now you will need a different computer program

- along with the tooling capacity - for each of those 20,000 parts

of your 2002 Honda Civic.

Do I do that? No. Can

I do that? No ... not just like that.

This is the experience

that people have come to expect. The overwhelming mystery process

none of us can wrap our minds around (unless you ever owned Ford

Motor Company) ... ;?) yet, we feel somehow familiar with the

saga, and feel we understand how the process works - and that

it's really pretty straight forward. Heck, we've seen it on the

History channel ... those wooden spoked model T wheels rolling

down the ramp ... caught just in time by the worker who slaps

it into a rim fitting machine ... and it rolls on.

Let's reel in the scale

some. Barnes Pneumatic. A vast amount of equipment spread over

a series of shops, yet no CNC equipment. Couldn't I have some?

Sure. Maybe one half decent older machine. Probably get one for

$25k. And, if it worked more than a month, I could program a few

operations on a couple of my parts. It won't make an entire airgun.

You see, these things are not magic robots. Some may exist that

will lathe turn, bore, mill, drill, tap, and polish while auto-changing

two dozen tooling set-ups during the process of making one part

from billet stock. Those machines are making parts for NASA. A

quarter of a million dollars will start you off on a small one

... then there's the service contract ... ;?)

Consider this. I can

make two nearly identical parts. I can make any replacement part

I need. It takes extra time though to make two identical parts.

To register them with one another. Now - ask yourself - for my

application ... why do it? The parts I make are good to go for

the next hundred years or so. What do you think is the chance

that someone is going to take apart one Barnes trigger block assembly

in order to swap an individual part out of it into a different

Barnes trigger block on a different rifle? Slim to none I'd think

- correct. So, is there a point for me to buy a new $50,000 CNC

mill that can be programed to produce three shifts worth of crates

each day full of secondary trip levers for a Barnes Chaparral

trigger block? Or ... should I have the $50K machine sitting there

for the five copies of that individual part I'll actually need

this year? Right ... I could have a hundred programs for a hundred

different parts ... or pcs. of those parts which my machine could

do ... while six other machines would be required to finish each

of the parts started on the fancy machine.

It's pointless to have

six thousand secondary trip levers really - unless I also have

six thousand of each of the other 99 parts of the rifle. See,

I'm not in the secondary lever business. That's exactly what I'd

have to be in if I had that machine. Instead, I understand the

"concept" of the trigger block. I have my mechanical

drawings with the dimensions I make them to. However; they are

fit individually ... according to the "concept" of their

inner workings which is imprinted in my head.

When you make the parts

by hand, you can make very similar parts, if you make all of the

same product year in and out. Of those parts that you make the

same, the parts will still vary a good bit. You see - there's

another BIG issue that people overlook. The issue of "DESIGN

TOLERANCE" . You can design a really sloppy project - with

really simple parts - and you can make them with a really wide

degree of variation ... and call them interchangeable ONLY because

the tolerances are so ridiculous wide in your design. Instead,

I make very intricate designs. The parts are fit with extreme

accuracy and exceptionally small tolerances. Those part are laid

in with the knowledge of the geometry of the parts - the time

is spent making this particular unit a fine as possible ... not

in making one lever from this unit fit into another unit a hundred

years from now. With my tools (which are very good but not state

of the art) I can make extremely fine work. I cannot make extremely

fine work that will interchange with my other extremely fine work

unless I'd devote five times the effort to making each part.

Therefore; if you were

that unskilled labor who was stuffing CNC made interchangeable

parts into interchangeable housings ... and you came to work at

Barnes Pneumatic ... you would be useless here. Here, you must

understand "concepts". You can't just stick a lever

into the trigger block. You must know the arc which the levers

are supposed to sweep. Know the geometry involved for engagement

and disengagement positions. Know the leverage which will generate

the force required for the minimal effort you wish to use. Know

by instinct, how to lay the parts on a blank side plate ... and

make a two stage trigger which actually has two stages.

I help people sort

out the site and the individual models. They ask: "Where's

the picture of the base model"? I answer: I've never

made one. "What?" No, the base model would be

just as custom as any other version. "You lost me".

You see, I don't have crates of base parts which are then dressed

up into fancy parts. I'd only make the base parts if I were building

a base model rifle. Otherwise, I build the parts required for

the individual build at hand. Crazy ... right?

Think about it ...

where would the base parts come from? Billet stock - custom machined.

So, why would I machine a plain trigger guard which really is

50% of the work of a fancy trigger guard? You see, we are so used

to buying upgrade parts for everything we own that we don't even

consider where the original parts come from. We take the original

wheels off of our vehicles and toss them in order to replace them

with custom wheels. Well, some person (or thing) made those original

wheels. Here at Barnes Pneumatic ... that would be me. So, I just

make the parts I need for the concept at hand ... not being bound

to start with some generic list of "base" parts ...

and thus the original "wheels" never exist. I go straight

to machining the custom ones I need.

What I've come to,

over the years, is a lifetime of "concepts" which I

build. This is NOT the non-sense you hear on TV where the guy

claims "I just start working and let the object tell me what

it wants to be ... ". That's absurd. You cannot build without

a vision. I "see" everything I make in advance. I know

that's not normal. But it makes me what I am. I work it thru in

my mind (often just staring into space where the mind's workbench

lies) and then go to paper once it's well worked out. I don't

make the first cut until I KNOW the thing is finished and working

in my head. Then, often, it's a drag to have to actually make

the parts. The creative process is then over and I'm relegated

to "technician" status for weeks of hard labor, following

my own mechanical drawings.

This is why I cannot

show you every version which I may have described as being possible.

The combinations are limitless. I often "know" that

this "concept" will work when applied. I can mix and

match those concepts, but the time consuming mechanical drawings

(with everything spelled out to the thousandth of an inch), must

be drafted prior to cutting steel. The vision is always several

steps ahead of the reality. It's only the reality that can be

photographed and put up on the site. I've often shown you concept

drawings - well in advance of making the airgun. I've done this

to have you become comfortable (while to a far lesser degree)

than I am with my ability to turn the concept into reality. You

see, I've been "me" for a long time now. I know what

I can do - and I've tried to share that with you. So, while industry

can show you their entire product line ... mine is in my mind.

Most recently, I've

morphed the business toward a "lego block" system of

these concepts that I can use to make anything I want to make.

It's the "process" - and not the individual part which

becomes interchangeable. I've referred to this last 18 months

of development as the "V-Twin" project. I'm going to

move to single out the models which use this technology from the

previous models. When I do so, some folks will be certain that

the previous works were flawed in some way. Not so - they just

required different mind sets and processes to make them. I won't

ever be able to drag myself into making endless copies of the

same thing. What I can do is make endless variations using similar

concepts which I've tooled for. You may see now that if I'd make

copies of the same thing over and over, they'd all still be individual

copies anyway. Can you imagine anything more alien to someone

like me than to invest all of the effort to make individual custom

parts for what appears to be stamped out clones. I get a shudder

just thinking of it.

I've proofed all the

concepts and processes at this point. We'll all benefit from the

results. If some wish to switch models, you know I've never scolded

you for that. The cost structures are identical - so - nobody's

being jumped up to anything they don't want. Everything on the

ledger will be made as promised when logged. I've had to complete

this "V-Twin" development project in order to keep the

business healthy for the future. It does produce the same quality

product - duplicate every performance characteristic - and yet

lower the stress level of dealing with public interest and demand.

Keep in mind too, I've

already put thirty years into my business. I'll never be able

to retire. Lowering the stress level is the gravy of my investment.

Happy Thanksgiving

I hope you all enjoy

a time of relaxation and find that you are blessed.

I plan to actually

do alittle shooting this morning. It's been way too long since

I shot for fun. I hardly even got to shoot at SS4 again.

We'll go to our Son's

home for a great meal later today. Yummmmm.

Been alot of mail correspondence

lately. I appreciate your notes. I'm moving projects along. Turning

the shop into a Bison workshop now. I'm into four of them good

folks are waiting for.

No ... nobody ever

took the free firewood. One of our Homestead friends said he'd

like to have it but I'd have to drive it to Alaska for him ...

;?) Hummmm ..... I had to haul it away.

It's been real good

to be in the shop working. I have the warm fuzzies with the thought

of the winter workshop and completing things.

We have a small group

committed to the Erwin Cup Pistol shoot - Jan. 15,16, '05 in Corbin,

Kentucky. That will be a fun time. Bob is fluffing up all the

targets for us.

Sorry I'm behind where

I'd like to be but I'm gaining some ground. I know I haven't posted

as much - been trying for alittle more shop time.

Some of you have picked

up on the "pistol" threads and asked about them. I'm

fascinated that there's so much that can be done with them that

answers what many people try to meet with their rifles. I agree

that the very low power short barrel variety of pistol are somewhat

limited. Those are great for indoor target and back yard enjoyment.

The "Pistols" I'm making are in a bit of a different

category. They're all "Pistol-Mags".

Mine are units that

could be at home in a small carbine stock. I started out making

things like this and got away from it as more and more folks were

intrigued by the big - long reaching rifles. Now I'm very much

enjoying both. My pistols are an interesting compromise. A third

to a half the weight of the rifles. About a quarter or a third

the length of a rifle. Yet my pistols are deadly accurate and

generate the power of most of the commercial PCP rifles of the

same caliber. Easy to store - easy to carry around. With power

adjust, easy to turn down for an indoor range if you wish. A neat

alternative.

Think I'll go shoot

a few rounds before Turkey! ;?)

Best of all to you

... Gary

11-19-04

Yes, I'm here. Thanks

for asking.

Working on parts. Working

on some crates for shipping. Worked on some more clean-up around

here. It's not the sort of thing you just give a kid a few bucks

to do. Not anymore anyway. Nothing's simple. I bought the place

in 1980. Young and stupid, I planted shade trees and yew shrubs

and ornamental trees and juniper bushes and juniper ground cover,

and azalea, and bamboo, etc., etc. Now, 25 years later, I'm ready

to lay waste to the whole darned forest. I must have been out

of my mind!

Thanks ... don't tell

me I was the last person on earth to find out that bamboo is aggressive.

Heard it all. Everybody else learned that in pre-school. Grew

up with a full knowledge of oriental horticulture. Well, I went

before they had pre-school ... so I missed all that. But I can

tell you things you don't even WANT to know about it now ... ha

ha ;?)

Story for you. I had

a bunch of construction materials stored - in waiting for a tool

shed addition to the shop. You know - the hundred hand tools,

the mower, snowblower, weed whackers, leaf blower, pressure washer,

chipper, mulcher, etc., etc.

So, the materials were

waiting there - in the way. And, one of these stupid ornamental

trees I'd planted - a flowering crab apple - was in the way -

they're ALL in the way. So, don't tell anyone ... I cut the thing

down. Then, the pile of tree brush and wood was in the way....

;?(

So, here and there,

I've moved the materials, cut the tree, moved the debris ... maybe

six months ago I framed the addition and roofed it ... later I

did alittle more. At this time, it has some cribbing up for walls

with some cedar shingle on the back - the weather side is just

a ladder work of cribbing the shingles go on. Whenever ... I have

no time to fiddle with it now.

So, many of these materials

that I'd accumulated were just never used. In the way. Some second

hand and ... waiting for years ... they were just not fresh enough

now. So, today, I cut up a bunch of 6 by 6 posts that were real

nice about 20+ years ago. Still solid ... but not what you invest

time into building with now. I'd acquired a bunch of packs of

1 by 3 lathing. I mean a dozen bundles of it or so ... but - weather,

cooking under tarps, bugs, etc. ... not fresh now. Cut it up.

Had some big limb stock - cut that up. Laid it all neatly in the

back of the truck. Cut into 3-4' lengths. Full load - tires showing

the weight and the truck down from the weight.

Around here, I've set

things out with FREE signs on them now and then, Usually gone

in half an hour. I decided someone could use all this clean firewood.

Put a sign out referring them around back to the truck - free

firewood.

All day, trucks drove

by in the alley - stopped - then drove on. So, good news ... the

economy is booming. Nobody needs a truckload of free firewood.

Maybe if it was seasoned split white oak and I'd deliver it and

stack it for them, someone would take it. Man, 25 years ago I'd

have thought it was Christmas if someone had given me this stuff.

Things have changed.

Still needing some

confirmation from a few for our Erwin Pistol Shoot. If you'd like

to spend the weekend with some folks enjoying Barnes Pistols,

let us know. You'll regret it for the rest of your lif.... well

... maybe not ... but we'd enjoy your company. It's intended to

be a small group and we have a few. But, for now, we have room

for a few more.

11-15-04 (amended

11-16-04)

If there's been a defining

discussion here on the website, I think this one - poised to snap

off of my fingers onto the keyboard may be it. You'll need a cup

of coffee or tea - and a few cookies. ;?)

Read it when you have

time to enjoy it. It's just a bunch of thoughts that came together

at this point.

How do I do this? I

mean ... really. Not how does the reservoir screw onto the valve

body, I mean .... HOW do I manufacture the products you see on

these pages. Some of you will find this fascinating ... some of

you will find it frustrating. Maybe this should be over on the

Homestead side, because it requires a simple faith in the fact

that I'm not "spinning" anything here. This is THE inside

information that goes to the core of Barnes Pneumatic. Ready?

OK, I've taught myself

to think in and to build "concepts". Concepts - not

artifacts. The one key invention which allowed the entire industrial

revolution was ..... "the interchangeable part". It

allowed unskilled labor to produce quality goods. Let me beat

that to death. That means that you can get a parts list for a

1963 Ford Falcon, and you can order up any of those parts, and

they will fit onto your 1963 Falcon. Big deal. So what?

Do you know what it

took to do that? Tens of millions of dollars for a start. A key

team of engineers design the concept. They are the ones who need

to know how the thing works. Not just that part # 465-KNY may

eventually be an exhaust valve for a six cylinder internal combustion

engine, rather ... they need to be able to DESIGN an internal

combustion engine and know what that exhaust valve needs to do.

What steel does it need to be made from? What shape does it need

to be. What diameter? What degree of bevel? What seat material

will it mate with? How will it be effected by heat? What spring

pre-load will snap it shut ... for the next twenty years and one

hundred million cycles?

Oh, eventually, you

can look that stuff up in mechanical engineering texts. Maybe.

Maybe if there is a text on the subject. Maybe if it's not a new

concept. Maybe if you can FIND the material you need and relate

it to the application you require. Then, maybe you can find some

of the information.

As the original engineer

however, you need to have an "instinct" for the original

concept. You need to be able to visualize your part in motion

... within the working swarm of all the other dependent parts

of the project. And then, you fabricate that prototype exhaust

valve - the one you saw in your mind. And, when it's complete,

you document the steps you took to make it. The casting and/or

machining. The lathe work. The heat treating. The dimensions.

The allowable tolerances.

For production, with

hundreds of thousands of dollars in equipment and labor, you set

up an entire system whereby workers (who know surprisingly little

about the given object), can run machinery which produces those

exhaust valves by the crate full. At that point, with sufficient

quality control and ongoing maintenance of equipment, you can

take any of those exhaust valves out of any crate and install

them into the engine of your 63 Falcon six cylinder.

Now, all you need is

to do the exact same thing for each of the other 20,000 parts

in the car.

We take all of this

for granted. It's the way industry has worked for the last 150

years. The interchangeable part, made by the thousand, was the

key. It requires factories - shifts of workers - vast tooling

maintenance - and incredible amounts of capital investment.

Fast forward. Do I

do that? No. Can I do that? No ... not just like that. Look into

the crystal ball again .... what did man do for the next generation

of the "interchangeable part"? Labor became organized

and expensive to maintain at about the same time as the electronics

revolution. Manufactured brains ... PC's ... came into being.

You didn't have to find a natural engineer who could visualize

the unknown. You just programed the PC's brain the do a repetitive

series of operations ... exactly the same for time without end.

And, to accompany the brain, you needed the most incredible computer

operated machine equipment ....CNC. You didn't specifically have

to make crates and crates of the same part (though you could).

In reality, you had your magic replicator which stored the method

of making your parts on demand. Your millions of dollars now transferred

from your labor force into your hardware investment. You began

to exist just to service the hardware. Keep it running. Keep the

brain cool and dust free. Make the payments on the equipment.

Fly in the specialized technicians to calibrate the things when

they go weird on you. Now you will need a different computer program

- along with the tooling capacity - for each of those 20,000 parts

of your 2002 Honda Civic.

Do I do that? No. Can

I do that? No ... not just like that.

This is the experience

that people have come to expect. The overwhelming mystery process

none of us can wrap our minds around (unless you ever owned Ford

Motor Company) ... ;?) yet, we feel somehow familiar with the

saga, and feel we understand how the process works - and that

it's really pretty straight forward. Heck, we've seen it on the

History channel ... those wooden spoked model T wheels rolling

down the ramp ... caught just in time by the worker who slaps

it into a rim fitting machine ... and it rolls on.

Let's reel in the scale

some. Barnes Pneumatic. A vast amount of equipment spread over

a series of shops, yet no CNC equipment. Couldn't I have some?

Sure. Maybe one half decent older machine. Probably get one for

$25k. And, if it worked more than a month, I could program a few

operations on a couple of my parts. It won't make an entire airgun.

You see, these things are not magic robots. Some may exist that

will lathe turn, bore, mill, drill, tap, and polish while auto-changing

two dozen tooling set-ups during the process of making one part

from billet stock. Those machines are making parts for NASA. A

quarter of a million dollars will start you off on a small one

... then there's the service contract ... ;?)

Consider this. I can

make two nearly identical parts. I can make any replacement part

I need. It takes extra time though to make two identical parts.

To register them with one another. Now - ask yourself - for my

application ... why do it? The parts I make are good to go for

the next hundred years or so. What do you think is the chance

that someone is going to take apart one Barnes trigger block assembly

in order to swap an individual part out of it into a different

Barnes trigger block on a different rifle? Slim to none I'd think

- correct. So, is there a point for me to buy a new $50,000 CNC

mill that can be programed to produce three shifts worth of crates

each day full of secondary trip levers for a Barnes Chaparral

trigger block? Or ... should I have the $50K machine sitting there

for the five copies of that individual part I'll actually need

this year? Right ... I could have a hundred programs for a hundred

different parts ... or pcs. of those parts which my machine could

do ... while six other machines would be required to finish each

of the parts started on the fancy machine.

It's pointless to have

six thousand secondary trip levers really - unless I also have

six thousand of each of the other 99 parts of the rifle. See,

I'm not in the secondary lever business. That's exactly what I'd

have to be in if I had that machine. Instead, I understand the

"concept" of the trigger block. I have my mechanical

drawings with the dimensions I make them to. However; they are

fit individually ... according to the "concept" of their

inner workings which is imprinted in my head.

When you make the parts

by hand, you can make very similar parts, if you make all of the

same product year in and out. Of those parts that you make the

same, the parts will still vary a good bit. You see - there's

another BIG issue that people overlook. The issue of "DESIGN

TOLERANCE" . You can design a really sloppy project - with

really simple parts - and you can make them with a really wide

degree of variation ... and call them interchangeable ONLY because

the tolerances are so ridiculous wide in your design. Instead,

I make very intricate designs. The parts are fit with extreme

accuracy and exceptionally small tolerances. Those part are laid

in with the knowledge of the geometry of the parts - the time

is spent making this particular unit a fine as possible ... not

in making one lever from this unit fit into another unit a hundred

years from now. With my tools (which are very good but not state

of the art) I can make extremely fine work. I cannot make extremely

fine work that will interchange with my other extremely fine work

unless I'd devote five times the effort to making each part.

Therefore; if you were

that unskilled labor who was stuffing CNC made interchangeable

parts into interchangeable housings ... and you came to work at

Barnes Pneumatic ... you would be useless here. Here, you must

understand "concepts". You can't just stick a lever

into the trigger block. You must know the arc which the levers

are supposed to sweep. Know the geometry involved for engagement

and disengagement positions. Know the leverage which will generate

the force required for the minimal effort you wish to use. Know

by instinct, how to lay the parts on a blank side plate ... and

make a two stage trigger which actually has two stages.

I help people sort

out the site and the individual models. They ask: "Where's

the picture of the base model"? I answer: I've never

made one. "What?" No, the base model would be

just as custom as any other version. "You lost me".

You see, I don't have crates of base parts which are then dressed

up into fancy parts. I'd only make the base parts if I were building

a base model rifle. Otherwise, I build the parts required for

the individual build at hand. Crazy ... right?

Think about it ...

where would the base parts come from? Billet stock - custom machined.

So, why would I machine a plain trigger guard which really is

50% of the work of a fancy trigger guard? You see, we are so used

to buying upgrade parts for everything we own that we don't even

consider where the original parts come from. We take the original

wheels off of our vehicles and toss them in order to replace them

with custom wheels. Well, some person (or thing) made those original

wheels. Here at Barnes Pneumatic ... that would be me. So, I just

make the parts I need for the concept at hand ... not being bound

to start with some generic list of "base" parts ...

and thus the original "wheels" never exist. I go straight

to machining the custom ones I need.

What I've come to,

over the years, is a lifetime of "concepts" which I

build. This is NOT the non-sense you hear on TV where the guy

claims "I just start working and let the object tell me what

it wants to be ... ". That's absurd. You cannot build without

a vision. I "see" everything I make in advance. I know

that's not normal. But it makes me what I am. I work it thru in

my mind (often just staring into space where the mind's workbench

lies) and then go to paper once it's well worked out. I don't

make the first cut until I KNOW the thing is finished and working

in my head. Then, often, it's a drag to have to actually make

the parts. The creative process is then over and I'm relegated

to "technician" status for weeks of hard labor, following

my own mechanical drawings.

This is why I cannot

show you every version which I may have described as being possible.

The combinations are limitless. I often "know" that

this "concept" will work when applied. I can mix and

match those concepts, but the time consuming mechanical drawings

(with everything spelled out to the thousandth of an inch), must

be drafted prior to cutting steel. The vision is always several

steps ahead of the reality. It's only the reality that can be

photographed and put up on the site. I've often shown you concept

drawings - well in advance of making the airgun. I've done this

to have you become comfortable (while to a far lesser degree)

than I am with my ability to turn the concept into reality. You

see, I've been "me" for a long time now. I know what

I can do - and I've tried to share that with you. So, while industry

can show you their entire product line ... mine is in my mind.

Most recently, I've

morphed the business toward a "lego block" system of

these concepts that I can use to make anything I want to make.

It's the "process" - and not the individual part which

becomes interchangeable. I've referred to this last 18 months

of development as the "V-Twin" project. I'm going to

move to single out the models which use this technology from the

previous models. When I do so, some folks will be certain that

the previous works were flawed in some way. Not so - they just

required different mind sets and processes to make them. I won't

ever be able to drag myself into making endless copies of the

same thing. What I can do is make endless variations using similar

concepts which I've tooled for. You may see now that if I'd make

copies of the same thing over and over, they'd all still be individual

copies anyway. Can you imagine anything more alien to someone

like me than to invest all of the effort to make individual custom

parts for what appears to be stamped out clones. I get a shudder

just thinking of it.

I've proofed all the

concepts and processes at this point. We'll all benefit from the

results. If some wish to switch models, you know I've never scolded

you for that. The cost structures are identical - so - nobody's

being jumped up to anything they don't want. Everything on the

ledger will be made as promised when logged. I've had to complete

this "V-Twin" development project in order to keep the

business healthy for the future. It does produce the same quality

product - duplicate every performance characteristic - and yet

lower the stress level of dealing with public interest and demand.

Keep in mind too, I've

already put thirty years into my business. I'll never be able

to retire. Lowering the stress level is the gravy of my investment.

Take a look at the

Chaparral, the Liberty, the Heritage, the Yukon, the V-Twin. You'll

note that they are not copies of anything, nor are they copies

of themselves. Yet - they are the result of this quiet revolution

here at Barnes Pneumatic.

Gary

1:53 AM - 11-16-04

11-14-04

Take a look at the

Chaparral, the Liberty, the Heritage, the Yukon, the V-Twin. You'll

note that they are not copies of anything, nor are they copies

of themselves. Yet - they are the result of this quiet revolution

here at Barnes Pneumatic.

Gary

1:53 AM - 11-16-04

11-14-04

Ahhh.... Fall of the

Year.

Here's about 25 bags

and those were all shredded - thus compressed. Be 4-5 times as

many otherwise I guess. And, we're about half done. My wife and

I always share this little saying ... "Gives you a good feeling

to do something for yourself ... doesn't it?" Actually, no

... it hurts a good bit right now ... ;?)

Heard from Bob. I've

been aware that he shoots his Chaparral 25 Pistol all the time.

Really uses it for enjoyment as it was intended. Can you believe

he's got 12-15k rounds thru that already? You know, I was wanting

to ask him how often he cleans the barrel. Before I could ask,

he gave me a report today and mentioned the fact without me ever

asking. He was talking about the amazing accuracy and mentioned

that he'd NEVER cleaned the barrel yet! That #3 buckshot is more

hard than soft lead and the barrel is just "right" -

evidently it doesn't get dirty.

Excerpt from today's

mail ....

Sleep well tonight Gary, knowing I'm doing by best

to wear it out and failing miserably.

Bob

11-12-04

Much improved - thanks.

Got one of those vac/shredder units

to help gather the tons of leaves on the property. Hey - nobody

told me you still have to push the thing and dump the bag every

ten minutes. Hummmm ...

Thank Heaven it's raining today and

I can't do any more of the leaves ... ;?)

Working on parts. That's the gravy.

Also putting in some more shop air

lines today. With those neat little dangly coil hoses dropped

from the ceiling. Tired of the tripping two step as they coil

in wait for me. Things are looking up. White tile and stainless

steel benches next I guess ... ha ha.

Back to it.

11-10-04

Feeling better during the days and

coughing myself to exhaustion at night. It's the gift that keeps

on giving ... ha ha.

Feels sooooooo good to be in the shop

cutting steel. I'm working. It's clear that I'm behind where I'd

like to be at this time. Interruptions come in all sorts of wrapping

paper. We try our best to cut out what can be cut out, yet keep

the business rounded and healthy. Personally, I know the line

between commentary and excuse gets blurred as time goes by. Just

let me say for the record, nobody suffers more than me for the

delays. But hey - I'm grinning while I run the lathe today.

We set the date for the Pistol Invitational.

Jan. 15, 16, '05. Remember, this isn't a Festival event like SS.

It's an invitational on private property. We just want a core

of friends there to enjoy it with us. We've had some interested

parties - you tell us if it's something you may wish to be included

in. There is no fee - it's a small event and Bob's already built

his pistol wonderland over the years.

I plan to whip his butt at the event.

By then that Chaparral 25 barrel of his will probably be shot

out ... he he. I think I set that one to lay down at 15k rounds

.... sneaky. Unless he got that 100 mpg carburetor version I had

set back for myself ... come to think of that ... where IS that

barre.....

11-05-04

Working on your orders. Replaced a

couple of critical parts I ruined (it happens). When it does,

I go back to bar stock and machine a fresh perfect replacement.

Trying to get a few sets of parts for

bluing. I'll be assembling the action of a Delta 32 /100 fpe version

soon as I get one critical part back from bluing.

Making plans for SS5. It takes the

whole year to get it right. We'll set the date asap. Still getting

photos from some of you and hearing what a great time you had.

Still fighting this miserable chest

cold. Living on cough syrup.

Heard from the Mom of the young man

whom we lost recently. She heard from the fella that received

Nelson's liver - all's well and he's exceptionally grateful. Guess

that's the ultimate example of making lemonade from lemons.

Tomorrow's Saturday ... I work on parts.

Ahhh.... Fall of the

Year.

Here's about 25 bags

and those were all shredded - thus compressed. Be 4-5 times as

many otherwise I guess. And, we're about half done. My wife and

I always share this little saying ... "Gives you a good feeling

to do something for yourself ... doesn't it?" Actually, no

... it hurts a good bit right now ... ;?)

Heard from Bob. I've

been aware that he shoots his Chaparral 25 Pistol all the time.

Really uses it for enjoyment as it was intended. Can you believe

he's got 12-15k rounds thru that already? You know, I was wanting

to ask him how often he cleans the barrel. Before I could ask,

he gave me a report today and mentioned the fact without me ever

asking. He was talking about the amazing accuracy and mentioned

that he'd NEVER cleaned the barrel yet! That #3 buckshot is more

hard than soft lead and the barrel is just "right" -

evidently it doesn't get dirty.

Excerpt from today's

mail ....

Sleep well tonight Gary, knowing I'm doing by best

to wear it out and failing miserably.

Bob

11-12-04

Much improved - thanks.

Got one of those vac/shredder units

to help gather the tons of leaves on the property. Hey - nobody

told me you still have to push the thing and dump the bag every

ten minutes. Hummmm ...

Thank Heaven it's raining today and

I can't do any more of the leaves ... ;?)

Working on parts. That's the gravy.

Also putting in some more shop air

lines today. With those neat little dangly coil hoses dropped

from the ceiling. Tired of the tripping two step as they coil

in wait for me. Things are looking up. White tile and stainless

steel benches next I guess ... ha ha.

Back to it.

11-10-04

Feeling better during the days and

coughing myself to exhaustion at night. It's the gift that keeps

on giving ... ha ha.

Feels sooooooo good to be in the shop

cutting steel. I'm working. It's clear that I'm behind where I'd

like to be at this time. Interruptions come in all sorts of wrapping

paper. We try our best to cut out what can be cut out, yet keep

the business rounded and healthy. Personally, I know the line

between commentary and excuse gets blurred as time goes by. Just

let me say for the record, nobody suffers more than me for the

delays. But hey - I'm grinning while I run the lathe today.

We set the date for the Pistol Invitational.

Jan. 15, 16, '05. Remember, this isn't a Festival event like SS.

It's an invitational on private property. We just want a core

of friends there to enjoy it with us. We've had some interested

parties - you tell us if it's something you may wish to be included

in. There is no fee - it's a small event and Bob's already built

his pistol wonderland over the years.

I plan to whip his butt at the event.

By then that Chaparral 25 barrel of his will probably be shot

out ... he he. I think I set that one to lay down at 15k rounds

.... sneaky. Unless he got that 100 mpg carburetor version I had

set back for myself ... come to think of that ... where IS that

barre.....

11-05-04

Working on your orders. Replaced a

couple of critical parts I ruined (it happens). When it does,

I go back to bar stock and machine a fresh perfect replacement.

Trying to get a few sets of parts for

bluing. I'll be assembling the action of a Delta 32 /100 fpe version

soon as I get one critical part back from bluing.

Making plans for SS5. It takes the

whole year to get it right. We'll set the date asap. Still getting

photos from some of you and hearing what a great time you had.

Still fighting this miserable chest

cold. Living on cough syrup.

Heard from the Mom of the young man

whom we lost recently. She heard from the fella that received

Nelson's liver - all's well and he's exceptionally grateful. Guess

that's the ultimate example of making lemonade from lemons.

Tomorrow's Saturday ... I work on parts.

I have a few photos from SS4 to share.

Hope you enjoy them.

I could sure go for a round of the

Wood's Walk again. I've added in the line of sight red line to

show you the target. This is Ger - a buddy from the Netherlands.

I think he was shooting a Falcon here.

What a beautiful setting that was ...

I could sure go for a round of the

Wood's Walk again. I've added in the line of sight red line to

show you the target. This is Ger - a buddy from the Netherlands.

I think he was shooting a Falcon here.

What a beautiful setting that was ...

Guido (another friends from the Netherlands)

shooting the Wood's walk with Cecil's Barnes Ranger Delta 32.

Guido (another friends from the Netherlands)

shooting the Wood's walk with Cecil's Barnes Ranger Delta 32.

Some of those targets were waaaaay

out. Guido did 19/20 with a Barnes 45 pistol. These steel swinger

targets (highlighted area) were at least 60 yards - mounted on

trees. Often there was brush and saplings in the way as well.

Some of those targets were waaaaay

out. Guido did 19/20 with a Barnes 45 pistol. These steel swinger

targets (highlighted area) were at least 60 yards - mounted on

trees. Often there was brush and saplings in the way as well.

Peter (Netherlands) shooting a Barnes

Liberty 25 on the Wood's Walk. The 25 caliber ball was extremely

accurate.

Peter (Netherlands) shooting a Barnes

Liberty 25 on the Wood's Walk. The 25 caliber ball was extremely

accurate.

Julio (Puerto Rico) shooting the Barnes

Yukon 58GS. You see why I like those 4X shotgun scopes?

Julio (Puerto Rico) shooting the Barnes

Yukon 58GS. You see why I like those 4X shotgun scopes?

"And then, I just wave my hand

over it like this ... "

Do you think Peter was buying it? ha

ha ... ;?)

(Actually - I was explaining the power

adjust feature of Peter's Liberty 25).

"And then, I just wave my hand

over it like this ... "

Do you think Peter was buying it? ha

ha ... ;?)

(Actually - I was explaining the power

adjust feature of Peter's Liberty 25).

_

_

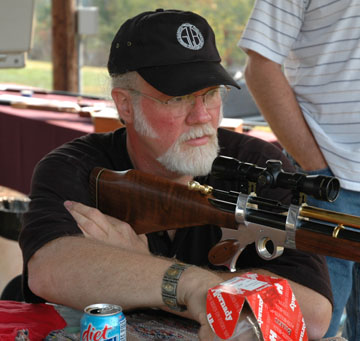

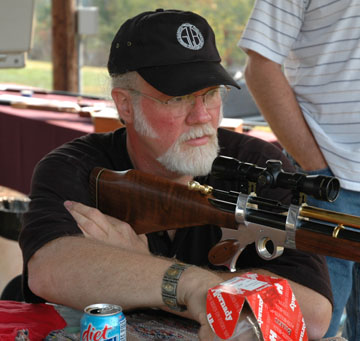

Here's Bob on the Woods Walk range.

Shooting a Barnes Chaparral 25 pistol. Note the shooting positions

were chosen to make it a challenge. Like hunting. Some targets

were clear - some obscured.

Here's Bob on the Woods Walk range.

Shooting a Barnes Chaparral 25 pistol. Note the shooting positions

were chosen to make it a challenge. Like hunting. Some targets

were clear - some obscured.

A blast from the past. Co2/low psi

PCP 45 caliber Pistol from about 6+ years ago.

A blast from the past. Co2/low psi

PCP 45 caliber Pistol from about 6+ years ago.

More

asap ... Gary

More

asap ... Gary

_

_

_

_

More

asap ... Gary

More

asap ... Gary