Back to Home / Complete

Index

Back To Quick

Index Page

***************Man At Work! **************

New stuff for 12-07-01

James' Tundra

Magnum 45

Got the first wet coat of oil on

...

_

_

_

_ _

_

_

_ It's soakin' in ... Gonna look real

fine ...

It's soakin' in ... Gonna look real

fine ...

I've started a new rifle. This is

a photo of progress so far. No, I'm not kidding.

Link to

Custom Gunsmithing

I've started a new rifle. This is

a photo of progress so far. No, I'm not kidding.

Link to

Custom Gunsmithing

The Weight-Reduction plan continues

. . .

No - not me. Our 9 lb. solid block

of steel (photo immediately above) has been the focus of some

intense machining operations. It now weighs between 3-4 lbs. Quite

a few more operations are still required.

Tactical 32 testing starts in October

2000

The Weight-Reduction plan continues

. . .

No - not me. Our 9 lb. solid block

of steel (photo immediately above) has been the focus of some

intense machining operations. It now weighs between 3-4 lbs. Quite

a few more operations are still required.

Tactical 32 testing starts in October

2000

This is a Ranger 25 Magnum action

which is currently in testing.

It's owner placed his order a few years

ago. Very soon now, and for the rest of his life, he'll have a

hot pcp varmint rifle which was custom built especially for him.

The "First Fire" celebration

is a special event around here.

We'll fit this rifle with my current

full barrel shroud moderator. To keep peace with the neighbors,

we must avoid supersonic rounds. This action shoots the 20.5 grain

Diana Magnum pellet @ 1096 fps - just under supersonic velocity.

The Beeman Kodiak, @ 31.2 grains (weighed),

fly @ 977 fps for 66.14 ft. lbs.

This is a Ranger 25 Magnum action

which is currently in testing.

It's owner placed his order a few years

ago. Very soon now, and for the rest of his life, he'll have a

hot pcp varmint rifle which was custom built especially for him.

The "First Fire" celebration

is a special event around here.

We'll fit this rifle with my current

full barrel shroud moderator. To keep peace with the neighbors,

we must avoid supersonic rounds. This action shoots the 20.5 grain

Diana Magnum pellet @ 1096 fps - just under supersonic velocity.

The Beeman Kodiak, @ 31.2 grains (weighed),

fly @ 977 fps for 66.14 ft. lbs.

Some of this new equipment I've

been talking about.

It takes alot of heavy, precise

equipment to make a bunch of small parts!

Added 10-20-00

Some of this new equipment I've

been talking about.

It takes alot of heavy, precise

equipment to make a bunch of small parts!

Added 10-20-00

I have a great stock going here

for a XXV Magnum - Nice vertical pistol / thumb hole design

I have a great stock going here

for a XXV Magnum - Nice vertical pistol / thumb hole design

How's that for a nice pc. of walnut?

How's that for a nice pc. of walnut?

Slow and easy with very sharp tools

- that's how to work highly figured woods like this.

Slow and easy with very sharp tools

- that's how to work highly figured woods like this.

Pressure Tube - Preparation for

acid etched total coverage detail

Pressure Tube - Preparation for

acid etched total coverage detail

Yes, every one of those details

is painted on by hand, one at a time!

Added 10-24-00

Yes, every one of those details

is painted on by hand, one at a time!

Added 10-24-00

And, the actual etching. Steel background

removed - design stands in relief.

And, the actual etching. Steel background

removed - design stands in relief.

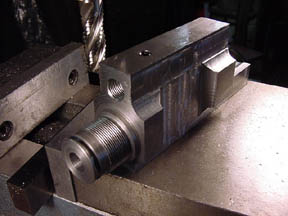

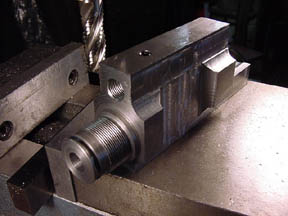

Folks always ask, "How long

does it take . . .?"

Well, here's a day's work. A "Billet

Construction" stock/reservoir/barrel clamp combination unit.

That's solid aluminum bar 3/4"

by 1 1/2". The back of the clamp is a hollow mortise, and

mates perfectly to the forestock's tenon extension.

Back to Home

/ Index Page

Folks always ask, "How long

does it take . . .?"

Well, here's a day's work. A "Billet

Construction" stock/reservoir/barrel clamp combination unit.

That's solid aluminum bar 3/4"

by 1 1/2". The back of the clamp is a hollow mortise, and

mates perfectly to the forestock's tenon extension.

Back to Home

/ Index Page

_

_

_

_ _

_ _

_