back to db page

Machine Work

On a Tundra Magnum with integral billet

steel receiver, I must connect the receiver block itself to the

hammer tube of the rifle. This connection must be literally "bullet

proof", as enormous stress is developed here with each firing

of the rifle.

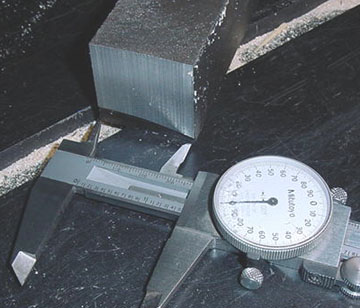

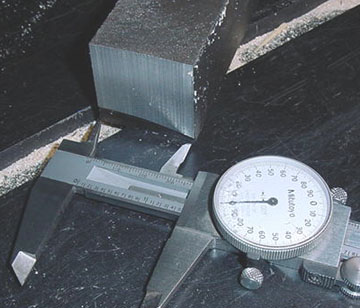

You see the interface hub starts life

as a billet of 1 1/2" by 1 1/2" by 3" solid mass

of steel. Band sawed from bar stock.

On a Tundra Magnum with integral billet

steel receiver, I must connect the receiver block itself to the

hammer tube of the rifle. This connection must be literally "bullet

proof", as enormous stress is developed here with each firing

of the rifle.

You see the interface hub starts life

as a billet of 1 1/2" by 1 1/2" by 3" solid mass

of steel. Band sawed from bar stock.

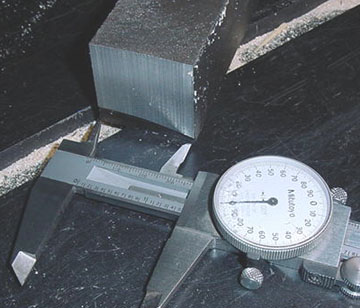

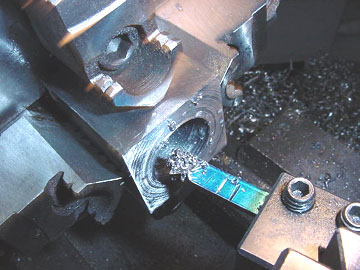

The billet is first faced each end

on the machine lathe, and then bored on the milling machine. The

hammer tube will be threaded into this hub.

The billet is first faced each end

on the machine lathe, and then bored on the milling machine. The

hammer tube will be threaded into this hub.

Back in the machine lathe, I'm using

a boring bar to prepare the hole to the exact size for threading.

Back in the machine lathe, I'm using

a boring bar to prepare the hole to the exact size for threading.

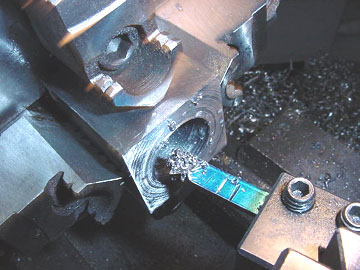

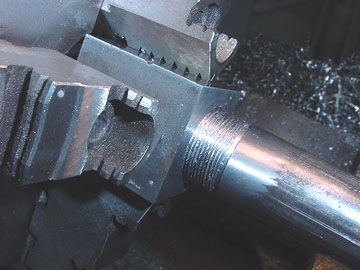

The hole at the proper diameter, I

now use a single point carbide 60 degree tool and chase the interior

threads. Maybe 20 or more passes will be required to make a clean

proper thread.

The hole at the proper diameter, I

now use a single point carbide 60 degree tool and chase the interior

threads. Maybe 20 or more passes will be required to make a clean

proper thread.

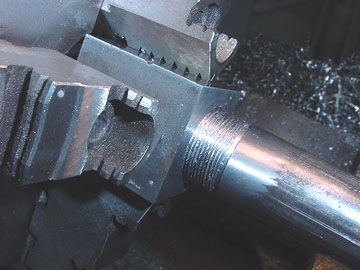

The 1" O.D. hammer tube (previously

exterior threaded in the lathe) is trail fit into the threaded

cavity.

The 1" O.D. hammer tube (previously

exterior threaded in the lathe) is trail fit into the threaded

cavity.

And everything precisely tuned until

perfect.

I'll show you more as I complete the

part - and show you where it goes. We will remove probably 80%

of the original billet material and weight in order to end with

the required machined solid steel part.

;?)

OK. Who says we're ready for bluing?

Page

2

And everything precisely tuned until

perfect.

I'll show you more as I complete the

part - and show you where it goes. We will remove probably 80%

of the original billet material and weight in order to end with

the required machined solid steel part.

;?)

OK. Who says we're ready for bluing?

Page

2